1

2

3

4

5

6

7

8

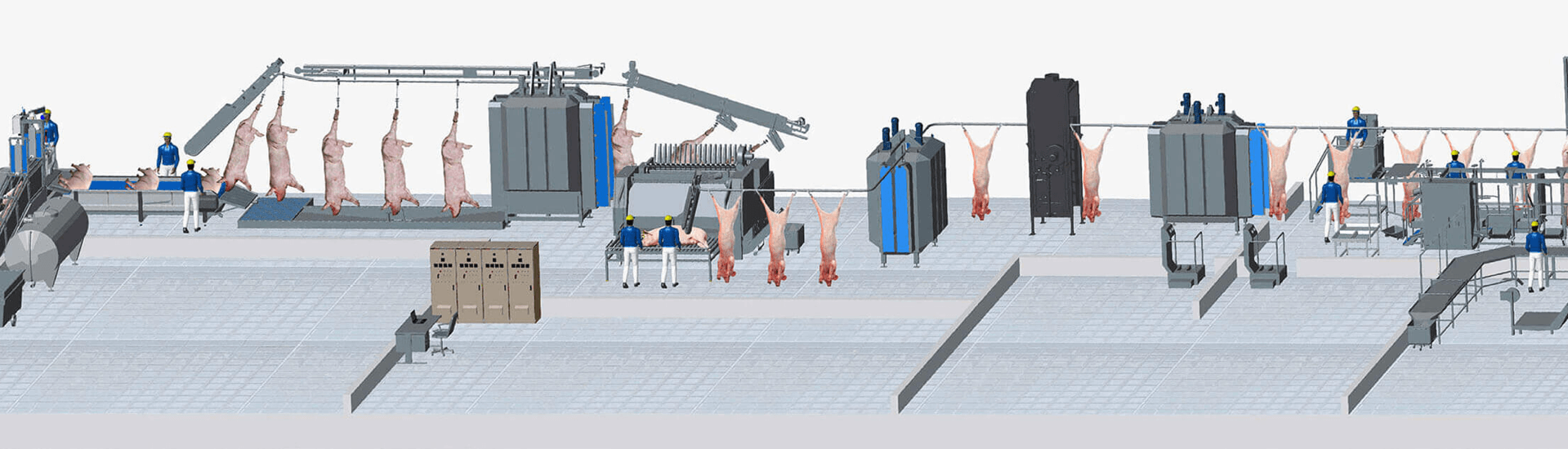

Cleaning and Dehairing Process

Pigs must be thoroughly cleaned and dehaired before evisceration. From a technological standpoint, this is a key procedure as the slightest irregularity in the execution can result in the incomplete dehairing or surface damage of the carcass, due to too rough a mechanical process.

The cleaning and dehairing of the pigs is mostly done automatically using several machines: carcass washers, evaporator, dehairing machine, drying machine and singer furnace. To ensure low production costs, the machines and transporters are synchronised.

We also offer the installation of a dehiding machine for larger pigs, which enables further processing of the pig’s skin into leather.

Highlighted features

- Selection of multiple carcass cleaning technologies.

- Almost completely automatic execution of the cleaning and dehairing.

- Synchronisation between machines ensures the efficient execution and low consumption of electricity.

- Minimal chance of carcass contamination.